The increase in the level of atmoshpheric CO2 and the resulting climate change are a global concern. Despite this, the use of fossil fuels continues to grow, in response to high energy demand. Combined with storage and CO2 conversion solutions, Chemical Looping Combustion processes (CLC) offer a medium-term solution to reducing the impact of energy production from fossil fuels, or even biomass. Essentially, they allow the generation of a flow of concentrated CO2 that can be captured, then stored or recovered [1].

To do this, these processes use oxygen carrier materials as a substitute for air in combustion, which are deployed in a high-temperature cyclical process, in which they are reduced by the fuel, then regenerated by oxydation. The repetition of these stages subjects them to significant stress - chemical, mechanical and thermal - which alter their lifespan.

Among these ageing mechanisms, a doctoral research projecta has examined in greater detail the migration of the active phase observed in oxydation-reduction cycles. Focusing on CuO-based oxygen carrier materials supported on Al2O3, the thesis characterised their change in operando conditionsb using a multi-scale and multi-technique approach.

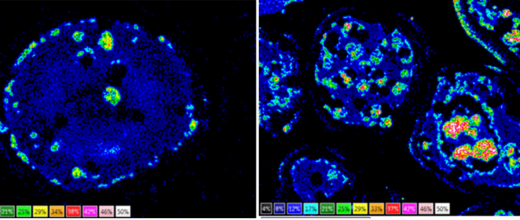

In the first instance, Environmental Transmission Electron Microscopy (E-TEM) made it possible to shed a light on the conversion mechanisms involved in the CuO/Cu active phase at the nanometric scale in reactive conditions [2]. It confirmed a very high mobility of the copper in these two forms: oxide and metallic, and showed evidence of the appearance of sintering phenomenac as of 500°C.

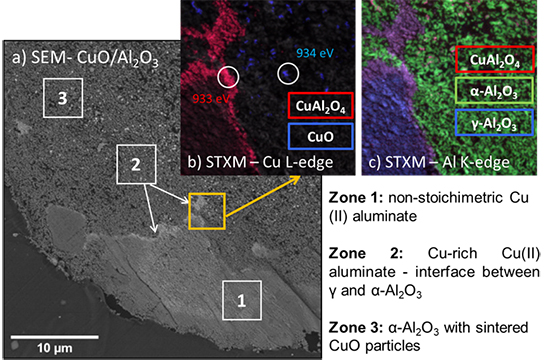

Subsequently, in addition to the usual techniques (SEM, XRD in particular), the original contribution of SXTM (Scanning Transmission X-ray Microscopy)d made it possible to precisely evaluate the structural and textural changes in the materials at the nanometric scale during oxydation-reduction cycles [3]. After change, a correlation can be observed between the textural properties and the chemical composition of the material’s various zones, and in particular the progressive formation of alpha alumina and CuO particles as of the initial copper aluminate (CuAl2O4) and gamma alumina phases. This is illustrated in the figure, which collates the SEM and STXM images acquired of a material that has undergone 50 redox cycles.

Following these observations, two mechanisms were proposed that would explain the change in the CuO-Al2O3 system. On the one hand, they relate to the phenomena of diffusion of copper-based species according to temperature, and on the other, the role of copper in the transition to the α-Al2O3 phase.

Thanks to this improved understanding of the phenomena of the mobility of supported copper-based phases and premature formation of alpha alumina, it will be easier to develop solutions to slow the ageing of materials during their implementation in CLC processes. This paves the way for the design of more stable oxygen carrier materials and the redefinition of their optimal operating conditions.

Click on the picture to enlarge

a- Thesis: « Understanding the mechanisms leading to copper migration in supported oxygen carrier for Chemical Looping Combustion », S. Sharna, University of Strasbourg, 2021

b- In representative operating conditions (reactive atmosphere, temperature and pressure)

c- Agglomeration and cohesion of particles when exposed to heat

d- Implementation on the HERMES line of the SOLEIL synchrotron

References:

- “Performance and degradation mechanisms of CLC particles produced by industrial methods”, A. Lambert, A. Tilland, W. Pelletant, S. Bertholin, F. Moreau, I. Clemençon, M. Yazdanpanah, Fuel, 2018, 216, 71-82.

>> DOI: 10.1016/j.fuel.2017.11.115

- “In-situ STEM study on the morphological evolution of copper-based nanoparticles during high temperature redox reactions”, S. Sharna, M. Bahri, C. Bouillet, V. Rouchon, A. Lambert, A. S. Gay, D. Chiche, O. Ersen, Nanoscale, 2021, 13, 9747-9756.

>> DOI: 10.1039/d1nr01648b

- “Effect of temperature and cycling on the grain-scale migration mechanism of copper”, S. Sharna, S. Stanescu, C. Bouillet, V. Rouchon, A. Lambert, A. S. Gay, D. Chiche, C. Legens, O. Ersen, to be published

Scientific contacts: David Chiche, Anne-Sophie Gay, Arnold Lambert