16.05.2022

3 minutes of reading

In partnership with Clermont-Auvergne University, IFPEN has developed a tool for predicting and scaling-up the performance of aerated bioreactors used in bio-based fuel production. This tool, based on numerical fluid mechanics, combines hydrodynamics, rheology, matter transfer and simplified microorganism metabolism.

Biofuel production: a major challenge for the energy transition

As an alternative to fossil fuels, ethanol derived from lignocellulosic biomass is associated with a reduction in greenhouse gas emissions while not competing with food-related agriculture. In order to reduce the production costs of this biofuel using enzymatic processes, one important lever is the optimization of enzyme production through filamentous fungi fermentation.

One of the main challenges associated with this step is the extrapolation of cultures from the laboratory scale, where tests are conducted, to industrial-scale production. That is because the supply of oxygen and substrates to microorganisms must remain optimal to maximize enzymatic productivity, a task made complex due to the non-Newtonian rheology of the fermentation medium (which reduces the transfer and mixing functions) and the sensitivity of the fungi to the shear stress generated by mechanical stirring.

Development of experimental methods to construct a reliable database

Since the exchange surface between the gas and liquid plays an essential role in oxygen supply to microorganisms, it is important to be able to predict the bubble sizes and volume fractions in the fermenters.

Bubble sizes in various media (fermentation filtrate, model media) were characterized using an optical sensor technique developed at IFPEN during previous research [1], but never before applied to non-Newtonian media [2]. These original measurements were reinforced by the determination of the gas/liquid transfer coefficient (kLa) in each of the systems studied, and the combination of the different results led to the development of a robust transfer coefficient (kL) model incorporating the impact of rheology and shear stress.

In addition, hydrodynamic characterizations - Mixing Time (via colorimetry and image processing) and Velocimetry (by Pavlov tube* ) - were conducted in the same aerated viscous media in order to build a numerical model validation database.

* Instrument used to determine the speed of a fluid, including for the two-phase scenario, from a pressure difference measurement

Use of predictive numerical methods

For the purposes of numerical simulation, a model was developed on the basis of a Eulerian two-phase approach [3] and an averaged description of velocity fields**. This model also integrates the oxygen transfer phenomena and the consumption metabolism for different substrates.

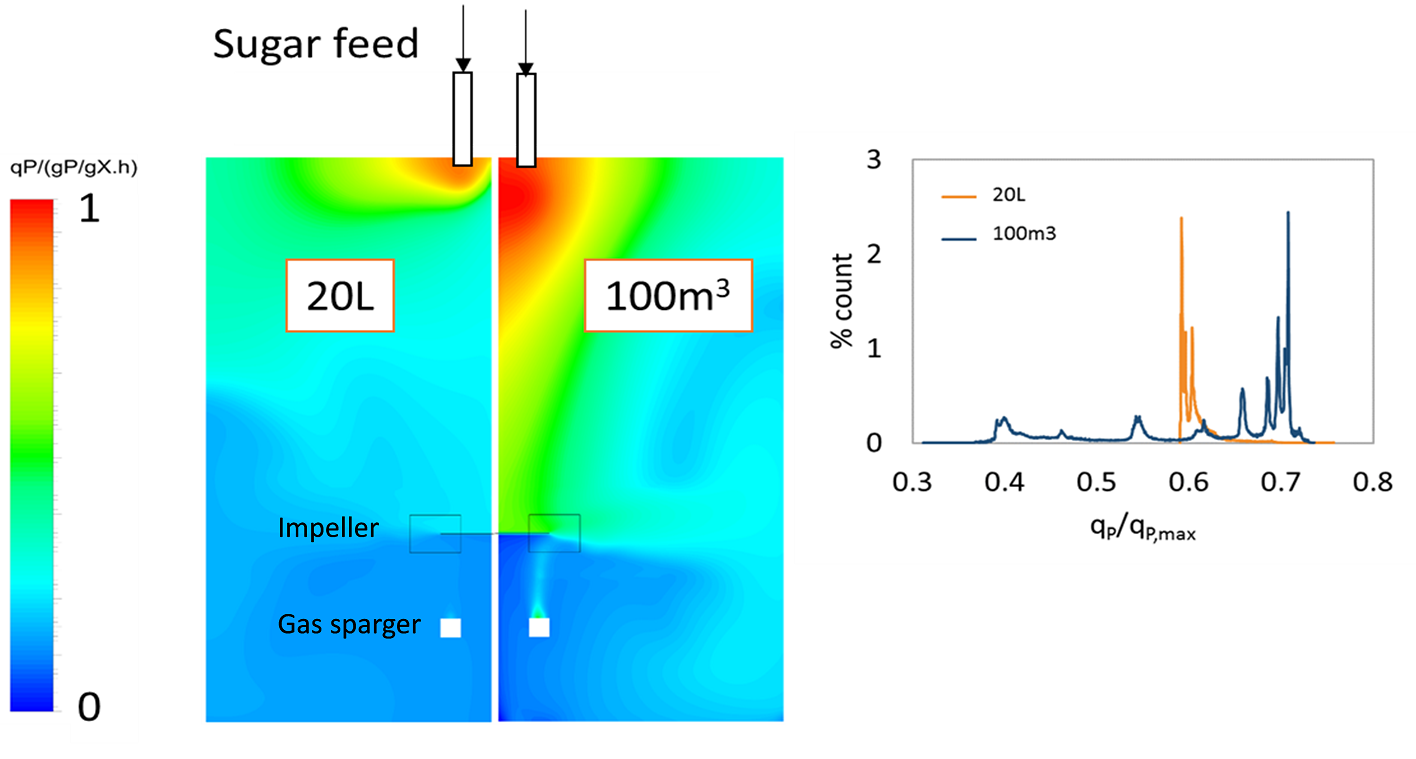

It allows the prediction, at all scales (laboratory, pilot unit, industrial), of sugar and dissolved oxygen concentration ranges, as well as the associated global protein (enzyme) productivity. It also provides a distribution of local enzyme productivity, as illustrated in figure 2 below, for two different-sized fermenters.

These calculations also highlighted an increase in metabolism heterogeneities with dimensional extrapolation, caused by substrate heterogeneities between zones. Consequently, there are potential differences in the behavior of microorganisms between the top and bottom of the fermenters.

** RANS approach : Reynolds Averaged Navier-Stokes equations

Towards increased incorporation of substrate variability

However, the metabolic model employed does not take into account the sensitivity of the microorganism to time-related and geometric variations in substrate composition. To fine-tune productivity predictions in large-sized fermenters, it is therefore necessary to evaluate the model’s ability to adapt to such fluctuations.

Tests to better characterize this aspect of the microorganism’s behavior are currently also underway in dual-zone fermenters, using a “scale-down” approach***.

Finally, the model will soon be used to validate stirring technologies and substrate injection methods aimed at ensuring the required level of homogeneity of substrates in order to maintain the optimal productivity of industrial fermenters.

*** Thesis underway by T. Goncalves Roque (IFPEN/AgroParisTech)

References:

[1] Maximiano Raimundo P., Analyse et modélisation de l'hydrodynamique locale dans les colonnes à bulles (Local hydrodynamic analysis and modeling in bubble columns), Thèse de doctorat, Université de Grenoble, 2015.

[2] Cappello, V., Plais C., Vial, C., Augier, F. (2020). Bubble size and liquid-side mass transfer coefficient measurements in aerated stirred tank reactors with non-newtonian liquids. Chemical Engineering Science, 211, 115280. DOI:10.1016/j.ces.2019.115280.

[3] Cappello V., Plais C., Vial C., Augier F., Scale-up of aerated bioreactors: CFD validation and application to the enzyme production by Trichoderma reesei. Chemical Engineering Science, 229 (2021), 116033. DOI:10.1016/j.ces.2020.116033.

Scientific contacts: Frédéric Augier, Cécile Plais