Numerous IFPEN applications, from liquid-liquid extraction for biofuel production to the flotation process for the separation of microplastics, bring into play interactions between a fluid and the large number of inclusions (bubbles, drops) it contains.

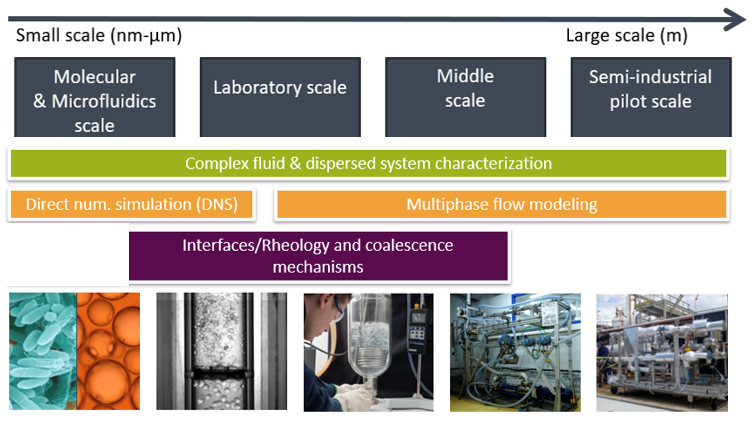

The difficulty involved in describing these interactions is related to the flows as such but also to the physical phenomena taking place on various scales: from colloidal forces acting on a molecular level through to hydrodynamic forces acting at flow level.

These forces are not independent. The physics of the interactions at the local level of the interface between the two phases (fluid and inclusions) govern the macroscopic behavior of the flow, via rupture/coalescence phenomena, and hence inclusion size as well. In turn, this size influences the hydrodynamic forces the inclusions are subject to.

No generally accepted theory exists to describe all of these phenomena. As a result, each new case study requires the performance of numerical simulations or experimental data acquisition. Molecular simulations and precise experiments make it possible to trace the interfacial properties of interest, essential for a precise description of rupture/coalescence phenomena.

Recent research of this type made it possible to trace the properties of the liquid-liquid and liquid-gas interfaces along which amphiphilic polymersa had been distributed [1]. In parallel, purely hydrodynamic simulations gave access to drainage times in imposed force liquid-liquid configurations [2]. The combined used of these two approaches is very promising in terms of obtaining the critical thickness for which the film breaks, with a view to injecting it into drainage time scaling laws. Moreover, it will lead to better determination of fluid and interface rheology, with the aim of direct integration in hydrodynamic codes, via constitutive laws.

An additional step to feed into engineering models (Euler-Euler-type) will be to consider a large number of coalescent inclusions and “average” their dynamics. In order to dimension industrial processes, it will then be possible to no longer consider each of the inclusions with its own movement in numerical simulations but, instead, an “averaged” fluid, leading to significant calculation time savings. The shift away from the models previously used towards this type of averaged approach is the focus of a research project conducted as part of a collaborationb with the CEA.

a- Having both hydrophilic and hydrophobic parts

b- Also involving IFPEN’s “Process Design and Modeling” division

References:

- I. Henaut, C. Nieto-Draghi, A. Mouret, C. Dalmazzone, V. Lachet. Rheological behaviour of amphiphilic polymers at liquid/liquid and air/liquid interfaces: Direct comparison of experiments and coarse grain simulations. GFR 2022, 56th Congress of the French Rheology Group, Rennes, 26-28 October 2022.

- J.-L. Pierson. Numerical study of a drop approaching a fluid-fluid interface: from sticking to bouncing. ICTAM 2021, 25th International Congress of Theoretical and Applied Mechanics, Milano (virtual), 22 to 27 August, 2021.

Scientific contacts: isabelle.henaut@ifpen.fr ; jean-lou.pierson@ifpen.fr ; Carlos Nieto-Draghi