30.11.2022

15 minutes of reading

The context of climate change and energy demand requires an acceleration in R&I efforts to develop the low-carbon technologies of the energy and ecological transition.

These developments necessitate multidisciplinary innovative research combining pragmatism with industrial realities and environmental constraints.

Research conducted within the Applied Physical Chemistry and Mechanics Division meets the need for a cross-cutting scientific approach.

By drawing on the complementary disciplines of its five departments, the division is able to offer several different ways of representing phenomena.

Irrespective of the applications considered, it is necessary to establish a dialog between different physics - and to do so on different scales - in order to explore, understand, characterize and model the behavior of materials and structures in their environment or that of complex fluids at the source of numerous phenomena involved in processes.

The ambitious objective we are pursuing is to connect the discrete and molecular world of physical chemistry to the continuous and more macroscopic world of mechanics and thermodynamics. To achieve this we draw on a pool of experimental and numerical tools, appropriate for the various study scales, and a solid bedrock of scientific knowledge, perpetually enriched by academic and industrial partnerships and via participation in collaborative projects.

We are delighted to give you the opportunity to explore the broad lines of this research through a few recent examples illustrating the four priority areas of our scientific policy: complex fluids, fluid/system interactions, electrochemical systems and structures in their environment.

We hope you enjoy reading these articles.

Thierry Bécue

Director, IFPEN Applied Physical Chemistry and Mechanics Division

Laurent Cangémi

Deputy Scientific Director, IFPEN Applied Physical Chemistry and Mechanics Division

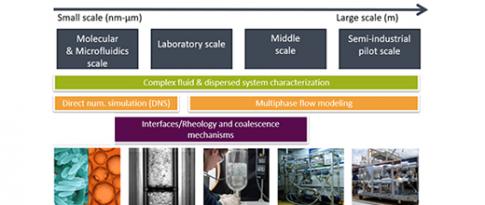

Coalescence and interfacial property: from the microscopic to the macroscopic

Numerous IFPEN applications, from liquid-liquid extraction for biofuel production to the flotation process for the separation of microplastics, bring into play interactions between a fluid and the large number of inclusions (bubbles, drops) it contains...

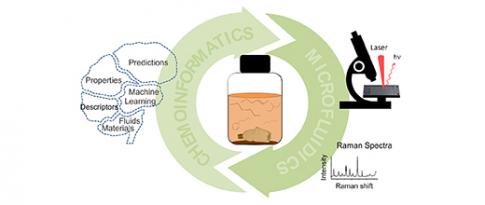

Microfluidics and Chemoinformatics: a highly complementary approach to studying material/fluid compatibility

Pour de nombreuses applications industrielles, comme le recyclage chimique des plastiques, ou encore pour assurer la compatibilité entre polymères et nouveaux carburants, il est essentiel d’anticiper les interactions entre matériaux et fluides...

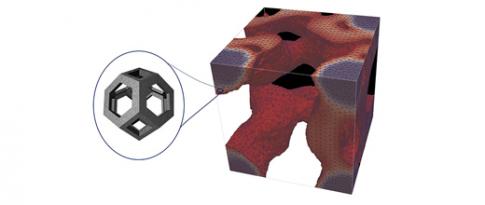

Materials for energy, a scale transition for an energy transition

Supported by its recognized experience in the development of energy production solutions, IFPEN has acquired in-depth expertise in the field of materials for functional use. Today, this expertise is being harnessed to address the emerging challenges of the energy transition...

Electrolyte thermodynamics at IFPEN

The field of electrolyte thermodynamics is a strategic one for IFPEN since it contributes to a number of its existing technological innovations, as well as those currently being developed...

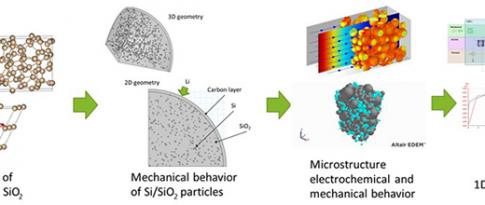

Battery behavior: a complexity best taken into account by modeling

For around fifteen years now, IFPEN has been focusing on modeling conventional batteries to represent their nominal operation (electric and thermal behavior during normal operation), throughout their lifetime (...) and in the event of thermal runaway (failure, improper use)...

“From material to structure” modeling: the case of anchor cables for offshore wind, in corrosive environment

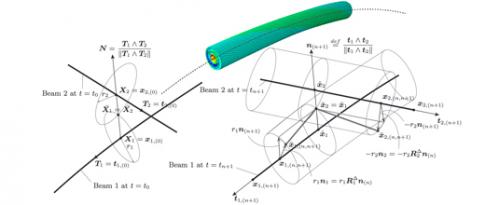

Anchor lines, the majority of which are carbon steel cables, are essential components for the stability of offshore floating structures, such as those supporting wind turbines. To overcome the risk of breakage during service, redundant lines are generally incorporated at the design stage, which adds significantly to the cost...

Wind farm optimization: in the wake of modeling advances

Wind energy accounts for an increasing share of the energy mix thank to the construction of wind farms designed to reduce investment and operating costs. However, within a farm, downstream wind turbines are exposed to the wakes of upstream rotors, leading to a reduction in their production and an increase in their fatigue stresses...